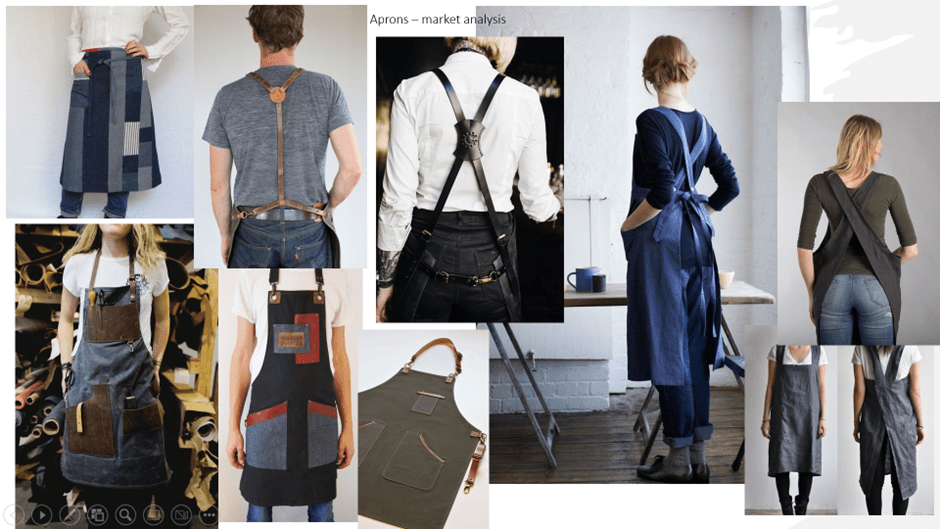

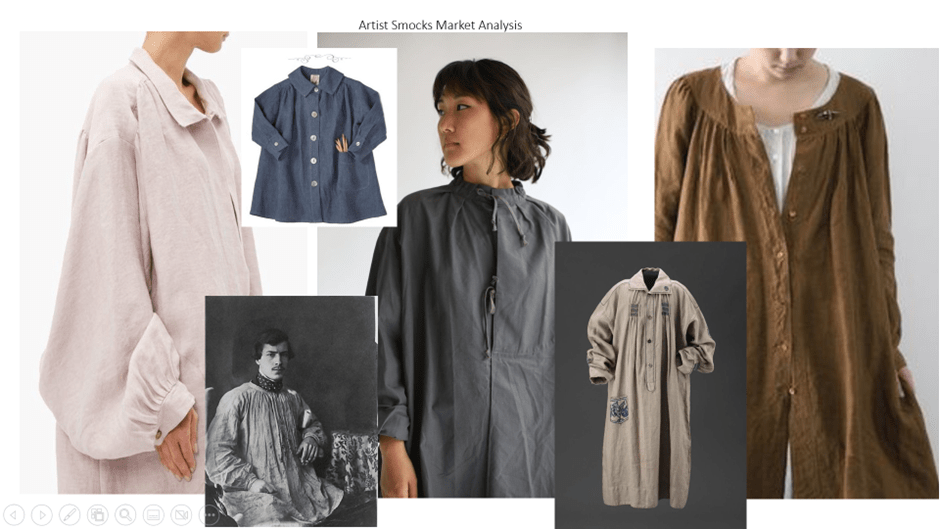

A strand of our business proposal is to facilitate workshops within the exhibition spaces (see blog post 5) but it wasn’t until 5 weeks into the project that I suggested some overalls might be useful for workshop attendees to wear and as a potential revenue stream. This proposal was well received by my teammates and I began visual research. I considered existing products that I had seen artists wearing when painting within the studio and gathered images of aprons, artist smocks, tabards and boiler suits.

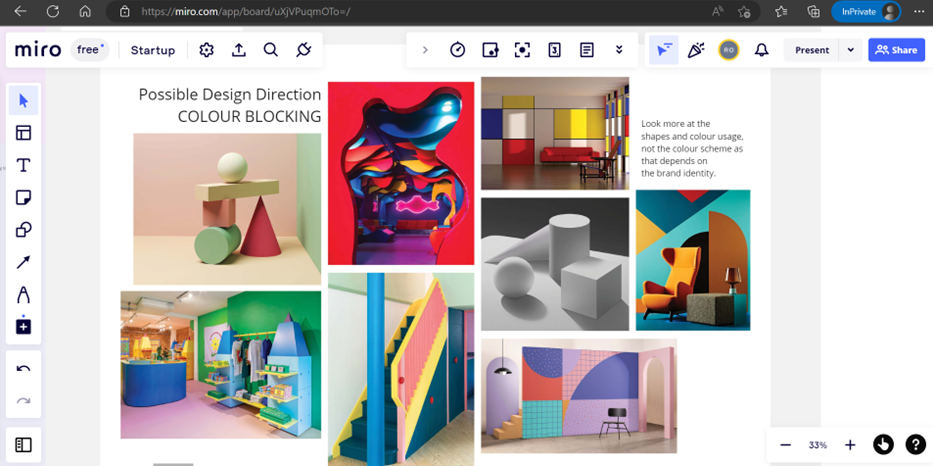

As ‘creatives’ we speak in a visual language and when we combine visual images, we can’t help but create new objects with surprising and unexpected emergent properties (Sawyer, 2017). Our group had been compiling images and research using the app, Miro (https://miro.com/app/board/uXjVPuqmOTo=/?share_link_id=70915905145 ). A digital whiteboard in which we could add concepts, images and text as our ideas developed.

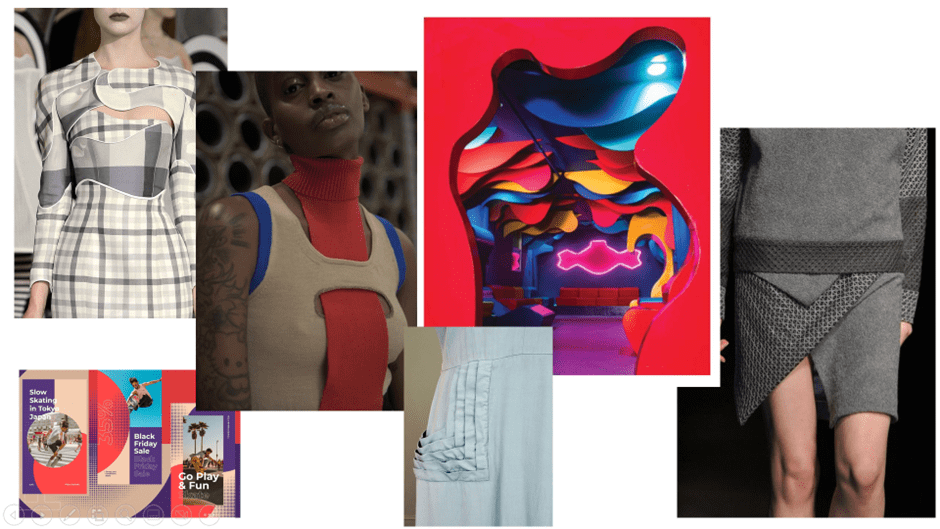

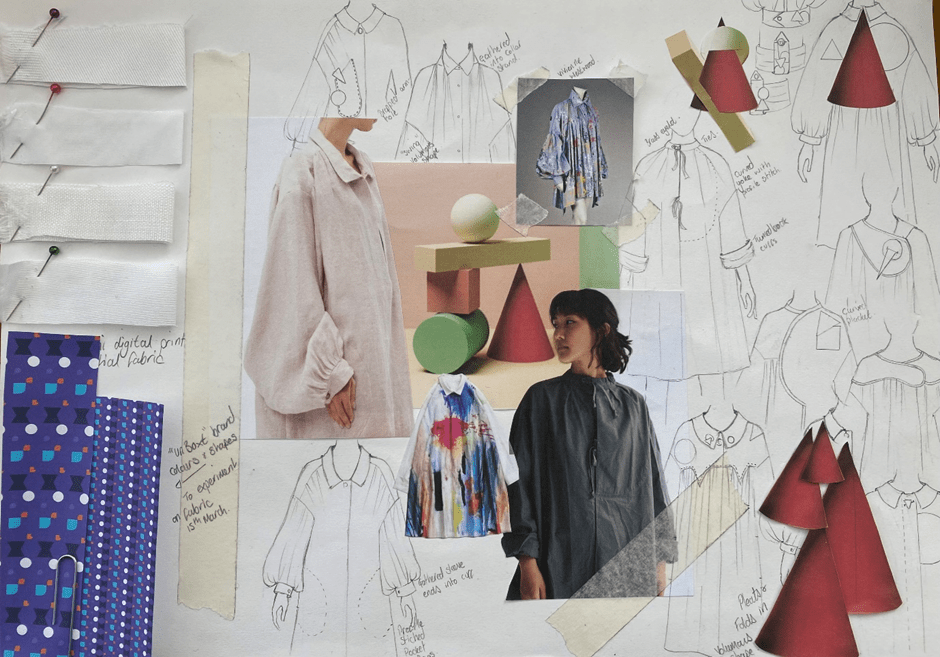

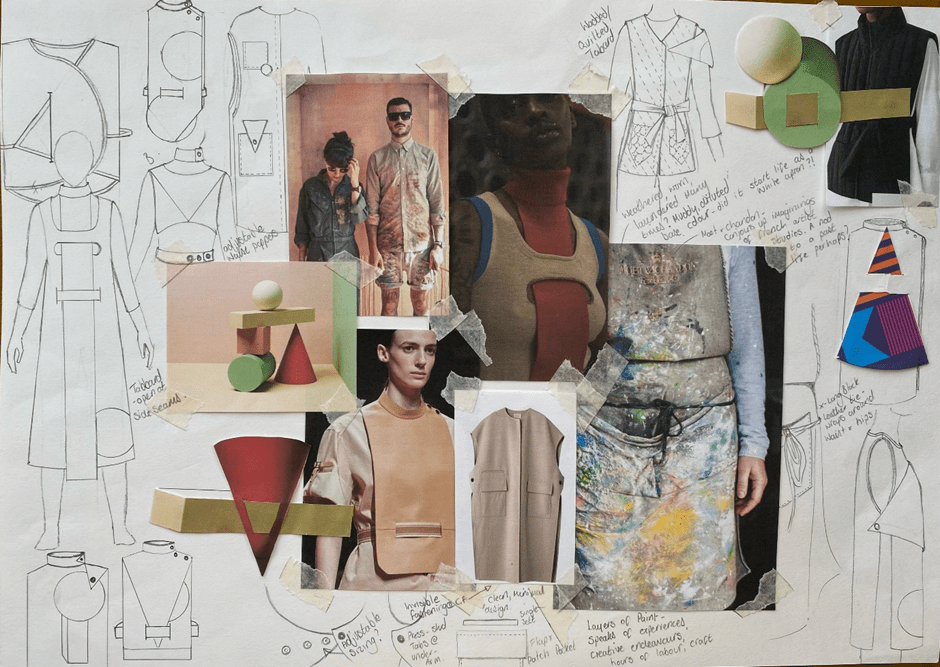

The Graphics and Interiors members of the group had added images of the design direction we envisioned for the project (figure 6), and I began to explore ways in which fashion and fabric print designers had designed in a similar aesthetic direction;

I developed this visual research further to generate my own ideas and concepts, blending the features of each product with ideas from the mood board. I worked on A3 cartridge paper and pencil to draw details, silhouette and form. This form of visual imagery is a powerful creativity technique for me because new combinations often appear suddenly, unpredictably, and spontaneously (Sawyer, 2017);

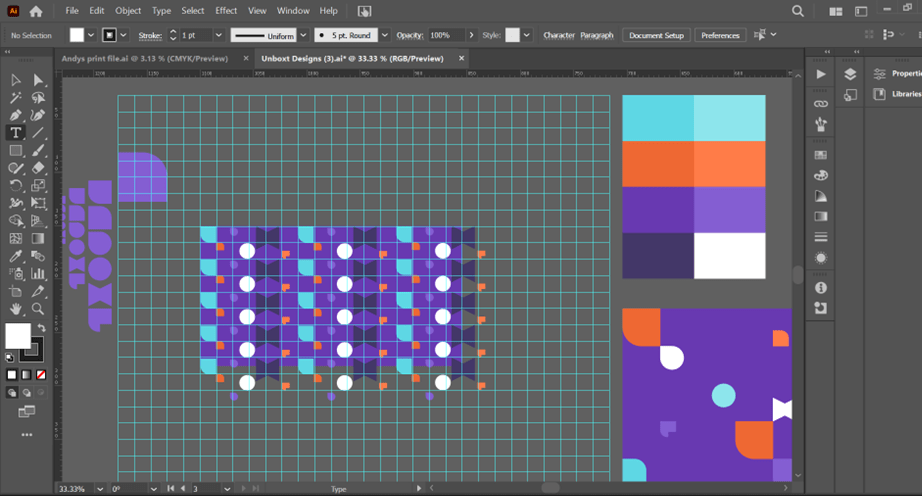

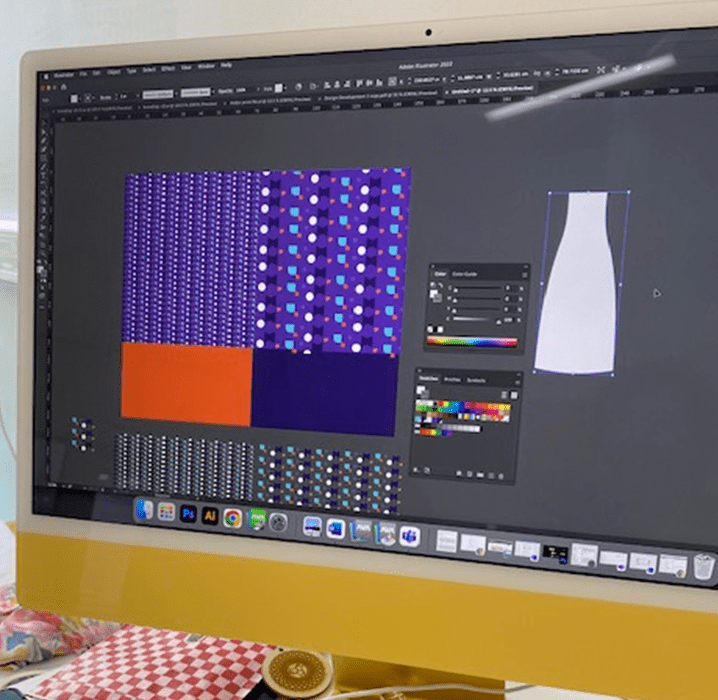

As my ideas and concepts developed, I could see the potential in developing the strong brand direction, proposed by my Graphics team mates, as a textiles print. After discussing this with our Graphics team members they developed an exciting system that made print generation easy using the software, Illustrator. I could place the logo shapes around the page in different scales and colour options until I finalised a print arrangement that I was happy with;

I had seen the digital print lab at the Barbara Hepworth building but had little knowledge of how this facility worked and took it upon myself to email them to request information on how the facility might support my ambitions to use print in my apron designs. I arranged to collect samples of the fabrics available to me and the print technician forwarded information of the two different types of printing that I could explore;

Option 1; The dye sublimation process transfers CAD prints onto polyester fabrics.

Option 2; The direct to textiles, pigment printing for pre-coated natural fibres.

I knew that Cotton Drill was typically used in kitchen ware from previous experience of making aprons, tea cosies and peg bags when I first started working as an independent dressmaker back in 2010-2014 and was happy to discover that the pigment printing technique is ideal for natural fibres such as Cotton. I am keen to utilise natural fibres through my practice as synthetic fibres are notoriously difficult to decompose and breakdown, so the ‘pigment printing’ option seemed ideal.

I appreciated the support of the technician, Laura Newill as I had limited skills in the software Illustrator, and she helped me to rework positioning of the print to enable a repeat that would work across 1.5 mtrs of cotton drill cloth.

I knew the dimensions of the cloth meant that I could cut two aprons from 1 meter of cloth, however I was thrilled to learn that I could split the design in two, meaning I could print half the width in the smaller scale and half in the larger scale print. On the screen I preferred the larger scale as it reminded me of the prints on the homewares at Orla Kiely, however I knew that the smaller scale would be useful for bindings, pockets and straps.

Laura also made the suggestion that, as I was paying for 1.25 mtrs and my aprons would be 80cm in length, I do not waste the cloth and print the remaining in a contrast plain. I therefore selected the orange and deep purple from the print to added this to the base;

It was hugely exciting seeing the digital print, developed on the screen, come to life! The colour combination of the palette was even more vibrant than I had anticipated, and I felt inspired for my next steps.

Next Steps;

- Develop the basic skills I have acquired in Illustrator. This is a software that I am keen to explore and include within my portfolio to support my progression.

- Digitally produce a range of design developments to present to my team mates to select the final range from.

References;

Orla Kiely. (2023). Apron in Linear Stem Slate. Orla Kiely. https://orlakiely.com/products/apron-linear-stem-slate