The final stage of my creative contribution to our group project was to make the aprons. My usual system of work for a project such as this is as follows;

1; Market research

2; Product research

3; Initial sketchbook ideation

4; Design Developments

5; Final product selection/prototype samples

6; Pattern cut and make product

7; Image capture of final product

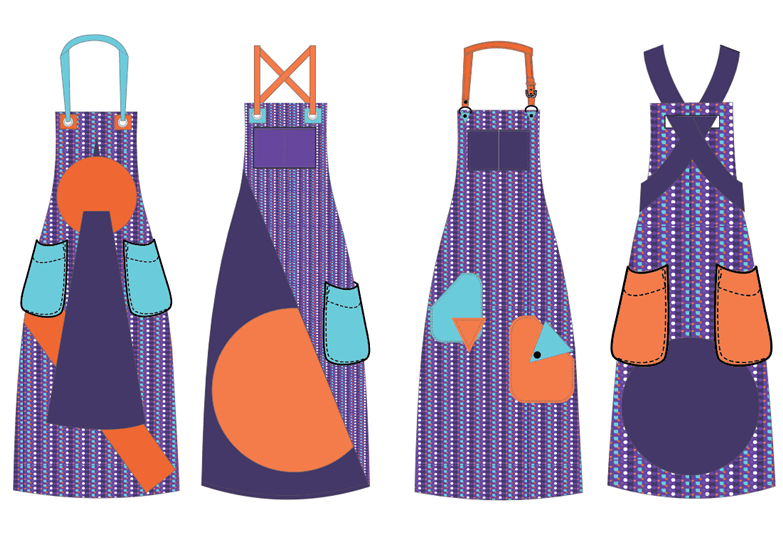

However, the time restraints upon us meant that I had to streamline my work flow and jumped straight into cutting and making the final designs without sampling details. I would have preferred to fully explore the ‘criss-cross’ of the straps in design 4 using calico fabric before embarking upon making with the bespoke digital printed fabric, however I decided to take the risk and embark upon the concept without fully exploring the idea. I was not satisfied with the ‘lay’ of the straps and, at the eleventh hour, discarded the idea and made a basic neck strap and waist ties.

I had to make other difficult decisions when considering workload and time frame and to be realistic in my ambitions I decided to make only two of the range of four. Many people say that they work better under pressure, but the Harvard researcher Teresa Amabile has found that this management tactic usually kills creativity. It makes people work harder, but it makes them less creative (as cited within Sawyer, 2017, P 192). I could have pushed myself to make the range of four aprons but didn’t want to loose the quality of the final outcome and believe that my decision to reduce the quantity to two has resulted in a better quality final product. It also allowed me to shift my focus to the essential group work required in the creation of our final presentation.

References;

Rigg, L. (2023). UnBoxt Aprons. [Photographs]. York, UK.

Sawyer, K. (2017). Group Genius (3rd ed.). Basic Books